Product total

$0.00

Shipping : Continue to next step

Total (tax incl.)

$0.00

Made in France

2-Year Manufacturer Warranty

Sold and shipped by Ligne Roset

30-Day Returns

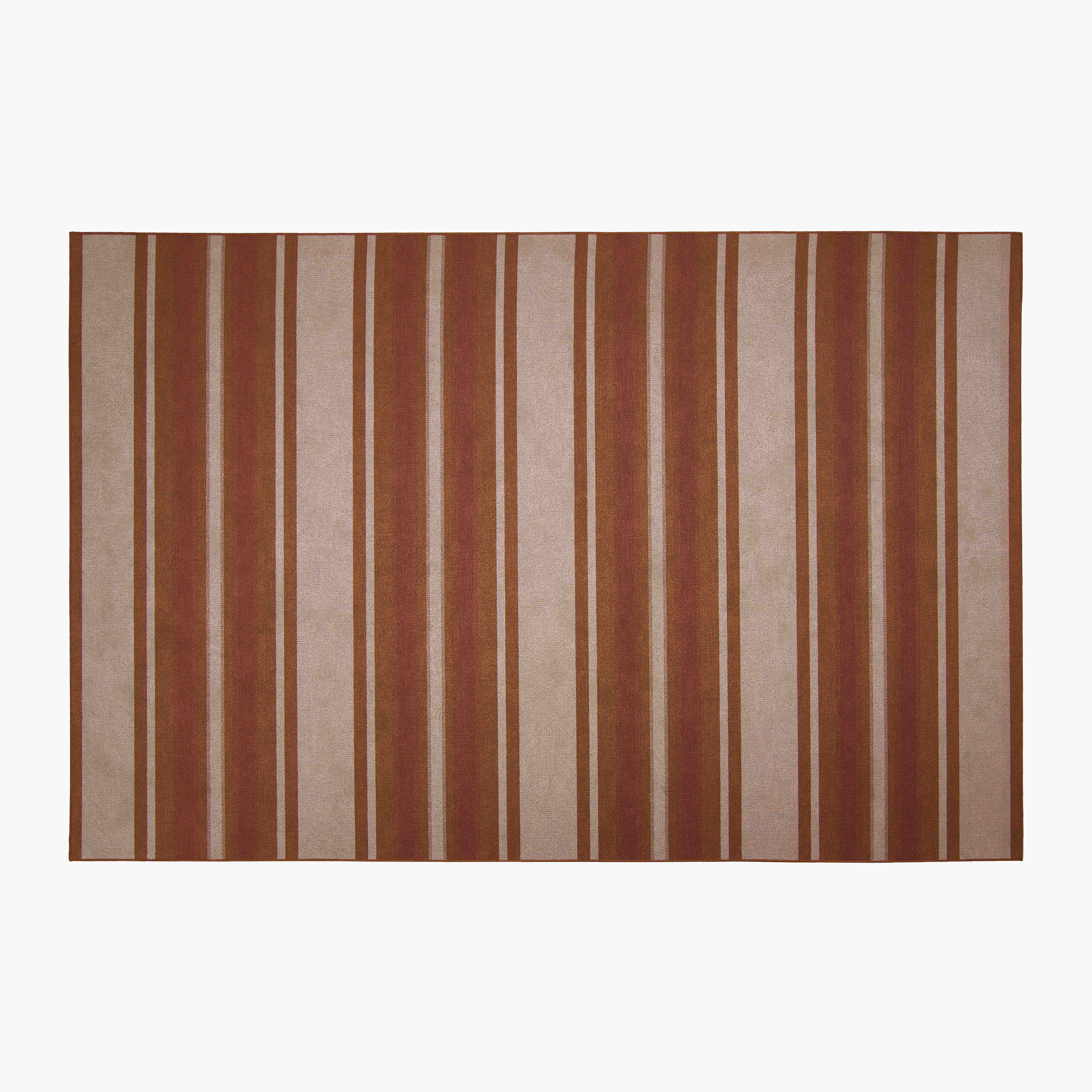

New fabric edited by Marie C Dorner

.jpg)

.jpg)

Your French made sofas available in 10 to 14 weeks !